1. The tire recycling history.

Since the production of the first rubber tires, there has been a need for tire recycling. Many processes were used, more “to get rid of” than to recycle the tires. Car and truck tires are easily shredded and eventually ground. Some methods focus on recycling methods for energy production, which is of course the end of life. Other methods […]

2. The search for the de-vulcanisation.

The real “recycling” operation has a very long history where the final goal was, and still is, de-vulcanisation of rubber for re-vulcanisation in new compounds. This recycling must be done in 2 steps: First the size-down of the tire into small grains and then as 2nd step, the de-vulcanisation of these grains. This process is done in a mechanical, […]

3. The quality of the de-vulcanisation.

It is obvious that the quality of the recycled de-vulcanised grains is depending on a number of issues. A major point is the cleanliness, another point is the consistency of the grains. Are they from the tread or from the side walls, or from both? Are they coming from conveyor belts, fenders or tracks? Evidently a new compound using de-vulcanised […]

4. The beginning of recycling and its limits.

To recycle tires, you need to reduce the tires into shreds and grains. However, there are limits. The economically limit of the maximum tire size is reached with a tire diameter of 1,4m. Above diameter 1,4m the handling and energy costs to shred (size reduction) and milling in granules is no longer profitable. The larger the tire, the higher […]

5. The history of UHP water jetting.

About 50 years ago, companies started to ‘recycle’ rubber tires using water jets. The last 2 decades 11 UHP (ultra-high pressure) pump manufacturers have significantly improved the performance of their UHP pumps and the linked roto-jetting to machine down the rubber. Some 45 patents were granted, 10 companies were testing “pulverizing” car and truck tires. The main questions are: Is […]

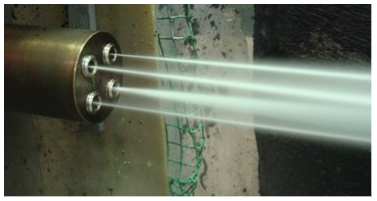

6. The choice of UHP water jetting.

There are 2 options: High water pressure, about 2.000 bar. Ultra-High waterpressure, about 4.000 bar. One can understand that the higher the water pressure, the greater will be the penetration into the rubber. BTRC has chosen the 2nd option with some 4.200 bar which is getting a 4 to 6cm penetration into the rubber and provides the best performance […]

7. A major issue: The required energy.

Optimizing the “pulverization” means using less energy (kWh/kg powder) and thus a higher yield (ROI-EBITDA). Consequently, the BTRC UHP water jetting process led to further in-depth research. The recycling of the big tires was a complex but interesting technical challenge. Initially, the focus was on the performance and the type of UHP pump. There are basically 3 main issues […]

8. The water quality, the great influence.

Water quality in the UHP water jetting process is a much more important element than initially was assumed and ignored in many applications. Of course “drinking” water quality is initially sufficient for any basic UHP water jet process, but there are many other “water” elements that significantly improve the yield. Surprisingly very little scientific information is available in this rather […]

9. The BTRC process.

1. The upstream process The upstream operation is preparing feeding water and the recycling of the water. The feeding water chemical quality, temperature and debit is monitored by this upstream process. The BTRC technology is using 11 water circuits to monitor feeding waters, UHP waters and recycling circuits. The use of buffer tanks is required to safe the treated recycled water […]

10. The UHP water jetting market.

Recycling other rubber products. The UHP water jetting is “pulverizing” the surface layers of rubber objects. The size and format of the End-of-Life (EOL) objects is not at all relevant for the recycling process. In other words: the rotojetters they do not know on what object they are pulverizing the rubber. Other EOL rubber products for recycling: Steel cord […]

11. International scientific papers.

The International scientific papers available on UHP water jetting do not provide sufficient back ground. The studies on the recycling of rubber comparing UHP water jetting to other ‘recycling’ methods are based on the UHP technology of some 20 years ago and consequently do not reflect the latest data. Multiple authors ignore the existence of different high pressures solutions. The […]